The steering systems fitted to motor vehicles can broadly be categorised into three types: (1) Mechanical hydraulic power steering systems; (2) Electro-hydraulic power steering systems; (3) Electric power steering systems.

I.Electric Power Steering System (EPS)

1. The full English name is Electronic Power Steering, abbreviated as EPS. It utilises power generated by an electric motor to assist the driver with power steering. Although the structural components differ across vehicles, the basic composition of EPS is largely similar. It typically comprises a torque (steering) sensor, an electronic control unit, an electric motor, a reduction gear, a mechanical steering gear, and a battery power source.

2. Primary operating principle: During steering manoeuvres, the torque (steering) sensor detects the steering wheel's applied torque and intended direction of rotation. These signals are transmitted via the data bus to the electronic control unit. Based on input data such as applied torque and intended steering angle, the ECU issues operational commands to the motor controller. The motor then generates an appropriate counter-torque output to assist steering effort. When no steering input is applied, the system remains inactive in standby mode, awaiting activation. Due to the operational characteristics of electric power steering, drivers typically perceive enhanced steering feel and greater stability at high speeds, commonly described as ‘steering that doesn't feel loose or vague’. Furthermore, its non-operational state during non-steering periods contributes to energy savings. This type of power steering system is commonly employed in premium saloon vehicles.

Compared to mechanical hydraulic power steering systems, electric power steering requires only electricity and eliminates numerous components. It dispenses with the hydraulic system's oil pump, oil lines, pressure/flow control valves, reservoir, and other elements. This results in fewer parts, easier layout, and reduced weight.

Moreover, it eliminates parasitic losses and fluid leakage losses. Consequently, electric power steering achieves approximately 80% energy savings under various driving conditions, enhancing the vehicle's operational performance. Consequently, it has seen rapid adoption in recent years and represents the future trajectory for power steering systems.

Some vehicles marketed as featuring electric power steering do not employ a genuinely pure electric system; they still require a hydraulic system, albeit one supplied by an electric motor. In traditional hydraulic power steering systems, the oil pump is driven by the engine.

To ensure light steering effort during stationary or low-speed manoeuvres, the pump's displacement is determined by the flow rate at engine idle speed. However, as vehicles spend most of their time travelling at speeds above idle and in straight-line motion, the majority of the oil pump's output must be returned to the reservoir via control valves, resulting in significant parasitic losses.

To mitigate these losses, an electric motor-driven oil pump is employed. During straight-line driving, the motor operates at low speed, while during steering manoeuvres it runs at high speed. By regulating the motor's rotational speed, the oil pump's flow rate and pressure are adjusted, thereby reducing parasitic losses.

II. Mechanical Hydraulic Power Steering Systems

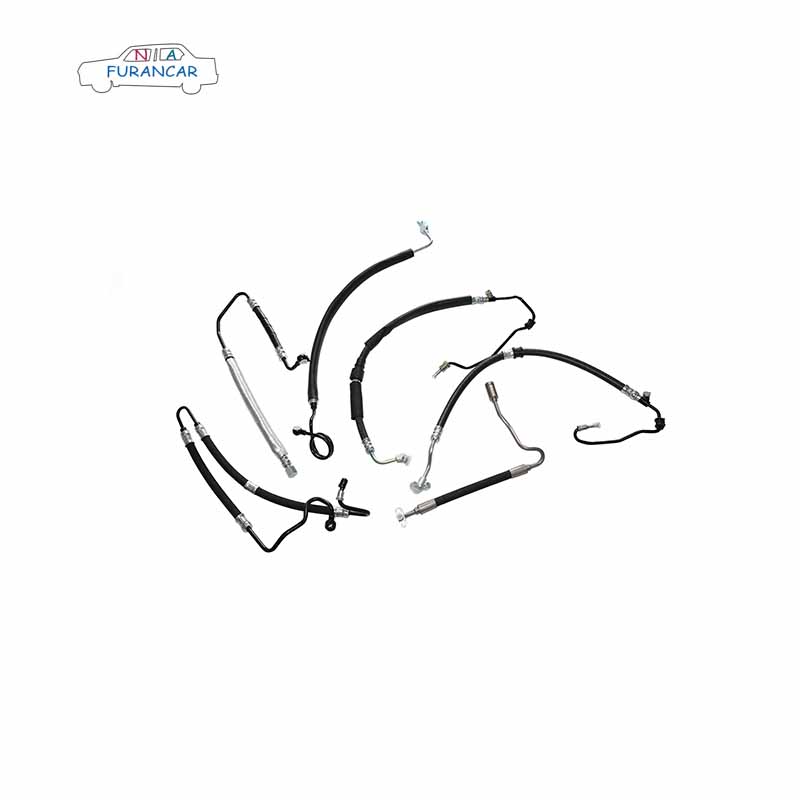

1. Mechanical hydraulic power steering systems typically comprise a hydraulic pump, oil lines, pressure-flow control valve body, V-belt drive, reservoir, and other components.

2. This system operates continuously regardless of steering input. During sharp turns at low speeds, the hydraulic pump must deliver greater power to provide substantial assistance, thereby wasting resources to some extent. Consider this: when driving such vehicles, particularly during low-speed turns, the steering feels heavy and the engine labours noticeably. Moreover, the high pressure generated by the hydraulic pump can readily damage the power steering system. Furthermore, mechanical hydraulic power steering systems comprise hydraulic pumps, piping, and cylinders. To maintain pressure, the system remains active regardless of steering assistance requirements, resulting in higher energy consumption – another factor contributing to resource expenditure. Such systems are commonly found in economy-class saloon cars.

III. Electronically Controlled Hydraulic Power Steering System

1. Primary Components: Reservoir tank, power steering control unit, electric pump, steering gear, power steering sensor, etc., wherein the power steering control unit and electric pump form an integrated assembly.

2. Operating Principle: The electronic hydraulic power steering system overcomes the shortcomings of conventional hydraulic power steering systems. Its hydraulic pump is no longer directly driven by the engine belt but instead utilises an electric pump. All operational states are determined by the electronic control unit, which calculates the optimal conditions based on signals such as vehicle speed and steering angle. Simply put, during low-speed, high-angle turns, the ECU drives the electric hydraulic pump at high speed to deliver greater power, reducing steering effort for the driver. At high speeds, the hydraulic control unit operates the electric pump at lower speeds, conserving engine power without compromising high-speed steering responsiveness.